|

|

||

Sub-Micron Precision Imaging System

Parlevision PSC is Parlec’s Proprietary Precision Imaging and Measuring Engine. It is at the Heart of Every Parsetter TMM System.

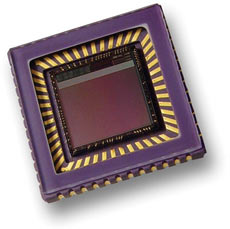

Advanced Imaging SystemUtilizing a MicronTechnology

DigitalClarity™ megapixel sensor, the ParleVision system is an embedded

computerized imaging control designed and manufactured exclusively by

Parlec that significantly reduces the pixel size, allowing our

programmers to create algorithms that resolve and measure at the

sub-micron level with incredible image stability.

A Team of ProgrammersA

team of programmers, hardware and software specialists create powerful

measuring and inspection capabilities and easy user interfaces. Because

our programmers have complete command of the camera architecture, quick

customization is possible to match our customers’ specific requirements. Real-time CrosshairsReal-time crosshairs automatically track the tool edge providing instant feedback of the measuring data. On-Demand Geometry DisplaysOn-demand

informational displays give the operator one-click access to insert

geometry for better control over the tooling process. High Resolution Surface InspectionLED Array provides cool, even illumination to inspect all aspects of the cutting tool surface. User-Accessible Camera CalibrationAll

cameras require regular calibration to correct for the effects of

temperature and humidity on the imaging surface. Only Parlec makes

these calibrations available, eliminating the need for costly service

calls. The user-accessible camera calibration of the Parsetter TMM® is possible due to its resistance to thermal expansion and distortion – simplifying the calibration of the measuring envelope. |

||

©2010-11 Jonathan Saada Inc. |