|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

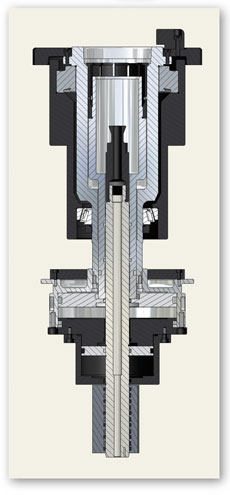

High Precision Quick Change Spindle System

For applications that require the utmost precision, Parlec’s HP Quick Change spindle system is the answer. Using dedicated cartridges for each tooling style, the HP spindle eliminates adapter stack-up and maintains the micron accuracy of the Series 2500 system – large diameter tooling, tapered tooling, and any tooling that must be set with micron precision can all benefit from the HP spindle system with universal mechanical power clamping options. On the ParleVision® CNC system, 3-axis automation, spindle focusing and auto-indexing are enabled. In addition, Parlec’s in-house engineering and design capability delivers custom tooling solutions fast for both milling and turning applications. The design of Parlec’s HP Quick Change Spindle maintains ‘match-ground’ precision, sealed bearing system, and elimination of adapter stack-up found in designs that utilize sleeved adapters.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

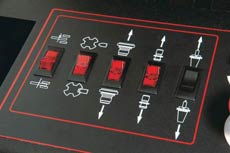

Convenient

panel controls provide easy access to spindle functions including

retention knob clamping, 90 degree and 360 degree spindle locking. Parlec’s High Precision Quick Change Spindle system is available on Series 2500 TMM machines. The system may be configured for manual operation and semi-automatic rotation using Parlec’s PGC Plus software. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| HP Spindle System | |||||||||

| Part Number | Style | Series | 90° Lock | 360° Lock | Clamping | Concentricity | Match Ground | Cartridge Changeover | Auto-Focus/Auto-Index |

|---|---|---|---|---|---|---|---|---|---|

| HPTBS-2500 | Quick-Change Cartridge | 2500 | Yes | Electronic | Vacuum or Drawbar | <.0005mm | Yes | 1 micron | Optional |

| HPTBSC-2500 | Quick-Change Cartridge | 2500 | No | Electronic | Vacuum or Drawbar | <.0005mm | Yes | 1 micron | Yes |

* 3° Insert Holders are standard and are included on Boring Head. Others are optional insert holders and are purchased separately, these are not recommended for dedicated production jobs. ** Note: Additional clearance required for nose radius above .016" |

|||||||||

Tool Cartridges & Accessories

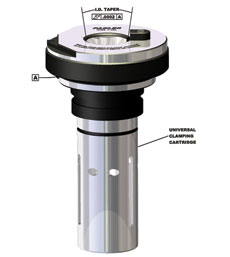

Tapered Tool Cartridges for HPQC Spindle

- For most SK, CAT and BT style tooling

- Precision machined from high-grade alloy steel

- Through hardened to RC 60-63 for high wear resistance

- Tapers ground to AT2 or better, per ISO 1947, for unmatched precision

- Integral gage sight in the cartridge eliminates the need for a separate zero gage for TMM mastering

- All tool cartridges are calibrated in our gage lab and shipped with certification documentation to ensure overall TMM measuring accuracy

With Universal Clamping

- Tapered tools are clamped by means of pneumatic-mechanical pull-down of the retention knob

- No change-out of clamping elements necessary

- Mechanical clamping improves tool run out and repeatability

- Compatible with all retention knob sizes offered in the Parlec tooling catalog

| Part Number | I.D. Taper | O.D. (mm) |

|---|---|---|

| HP30-QCTP | ISO 30 | 111.76 |

| HP30-QCTPU (Universal Clamping) | ISO 30 | 111.76 |

| HP40-QCTP | ISO 40 | 111.76 |

| HP40-QCTPU (Universal Clamping) | ISO 40 | 111.76 |

| HP50-QCTP | ISO 50 | 111.76 |

| HP50-QCTPU (Universal Clamping) | ISO 50 | 111.76 |

| HP60-QCTP | ISO 60 | 158.75 |

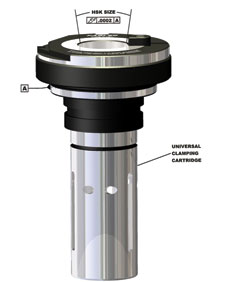

HSK Tool Cartridges for HPQC Spindle

- For all series HSK style tooling

- Precision machined from high-grade alloy steel

- Through hardened to RC 60-63 for high wear resistance

- Manufactured per DIN 69063

- HSK tools are clamped by means of electro-mechanical pull down

- Integral gage sight in the cartridge eliminates the need for a separate zero gage for TMM mastering

- All tool cartridges are calibrated in our gage lab and shipped with certification documentation to ensure overall TMM measuring accuracy

| Part Number | HSK Size | “Z” Height (mm) |

|---|---|---|

| HPH32-QCTP | 32A/40B | 4.32 |

| HPH40-QCTP | 40A/50B | 4.32 |

| HPH50-QCTP | 50A/63B | 4.32 |

| HPH63-QCTP | 63A/80B | 4.32 |

| HPH80-QCTP | 80A/100B | 32.00 |

| HPH100-QCTP | 100A/125B | 32.00 |

CAPTO Tool Cartridges for HPQC Spindle

- Precision machined from high-grade alloy steel

- Through hardened to RC 60-63 for high wear resistance

- Integral gage sight in the cartridge eliminates the need for a separate zero gage for TMM mastering

- All tool cartridges are calibrated in our gage lab and shipped with certification documentation to ensure overall TMM measuring accuracy

| Part Number | “Z” Height (mm) | CAPTO Size |

|---|---|---|

| HPC3-QCTP | 70.10 | C3 |

| HPC4-QCTP | 80.30 | C4 |

| HPC5-QCTP | 90.20 | C5 |

| HPC6-QCTP | 127.00 | C6 |

| HPC8-QCTP | 144.00 | C8 |

VDI Tool Cartridges for HPQC Spindle

- Precision machined from high-grade alloy steel

- Through hardened to RC 60-63 for high wear resistance

- Integral gage sight in the cartridge eliminates the need for a separate zero gage for TMM mastering

- All tool cartridges are calibrated in our gage lab and shipped with certification documentation to ensure overall TMM measuring accuracy

| Part Number | Size | “Z” Height (mm) |

|---|---|---|

| HPVDI20-QCTP | VDI20 | 54.61 |

| HPVDI30-QCTP | VDI30 | 54.61 |

| HPVDI40-QCTP | VDI40 | 54.61 |

| HPVDI50-QCTP | VDI50 | 101.60 |

©2010-11 Jonathan Saada Inc. |